Anova Industrial Gateway™

Industrial Gases, Liquified Natural Gas

Worldwide

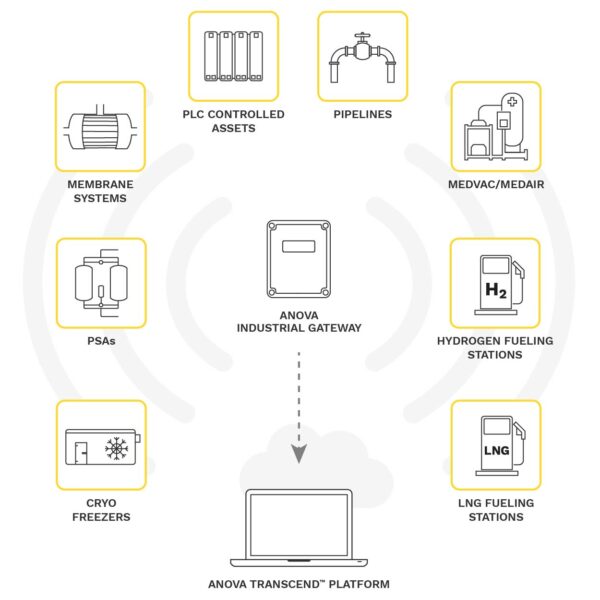

Advanced Industrial Asset Monitoring: The Anova Industrial Gateway digitizes more of your supply chain. With robust, integrated data collection, and comprehensive analytics, gain fast, actionable, operational insight. Mitigate risk, enhance safety, and reduce downtime for your operations with customizable alerts and real-time notifications. Monitor critical operating parameters from multiple advanced systems assets, side-by-side with your tanks, including cryogenic freezers, pipelines, membrane systems, PSAs, MEDVAC and MEDAIR systems, Hydrogen and LNG fueling stations, and PLC-controlled assets.

- CAPTURE CRITICAL DATA – Expand the scope and visibility into your operations by connecting more assets into your monitoring dashboards. Comprehensive support for multiple measurements including pressure, flow rate, temperature, and others.

- VISUALIZE NEW INSIGHT - Make informed, proactive decisions with an extensive analytic view into the performance and efficiency of multiple industrial assets.

- UNLOCK NEW VALUE FOR YOUR CUSTOMERS - Maximize operations by actioning new insight to reduce customer maintenance costs and downtime, while improving customer service and supply chain efficiency.

- ENABLE CUSTOM ALERTS- Ensure safety and enable preventive maintenance with custom thresholds to trigger automated alerts and notifications.

- POWERFUL ANALYTICS- Create customized reports and beautifully visualized custom charts to gain actionable insight into your operations.

- INTEGRATED ERP CONNECTIVITY- Exchange and share data with back-office systems, including SAP and others.

- EXPERT CUSTOMER SUPPORT- Dedicated technical support with decades of experience in industrial gases, chemicals, and software integration.

| Dimensions | 15.7” (L) x 11.8” (W) x 7” (H) / 400 (L) x 300 (W) x 180mm (H) |

| Radio | North America: LTE 4G/3G International: LTE 4G/3G/2G |

| Sensor & Gauge Input | Analog: Up to 20 Digital: Up to 32, Counter inputs shared with digital channels, number depending upon configuration |

| Power Inputs | Mains with battery backup or DC powered, 12-24 VDC |

| Battery Life | Also supported with battery backup |

| Reporting Schedule | Configurable data logging, reporting schedule, and alerts |

| Material | Enclosure: Polycarbonate, Display (optional), Din rail mounting |

| Temperature Range | Working: -25°C to +60°C / -13°F to 158°F Storage: -40°C to +70°C / -40°F to +158°F |

| International Protection Marking | CE, UL/CSA, FCC, RED IEC 60068-2-6/27/64 vibration and shock Some also compliant to IEC 60068-2-1/2/14/30 temperature |